Within the flue gas cleaning of a waste incineration plant, multi-stage pollutant separation takes place using dry, quasi-dry and wet processes. The reduction of HCl, SO2, HF and heavy metals including Hg takes place in multi-stage scrubbers, whereby the recycling of acid or gypsum can close industrial material cycles.

While acid and alkaline scrubbing can be considered standard processes, substances such as mercury require special technologies. In order to minimise the residual material flows resulting from waste incineration, processes such as the 3R process for filter dust leaching are coming to the fore.

Our range of services extends from the targeted separation of mercury to the treatment of heavy metal eluates and the multi-stage treatment of scrubber effluents. Process engineering sub-processes such as CO2 stripping, heavy metal precipitation/neutralisation, post-precipitation using TMT, sedimentation, ammonium reduction, polishing (filtration, activated carbon and ion exchangers) and sludge dewatering are used.

Due to the upstream thermal process, the temperature control of the waste water always plays a key role in complying with the required limit values and minimising gypsum/calcite scaling in the system.

We offer the planning, procurement, delivery and installation as well as supervision and commissioning/documentation of the complete wet section including sludge treatment.

-

Industrial Plants

Construction and commissioning of process plants for water treatment is based on interdisciplinary experience. In addition to the mining and… -

Laboratory- / Pilot Tests

Laboratory testing and pilot testing are often compulsory for a sound concept development and optimal solution. We plan and execute these… -

Pilot Container

Based on your technology concept, we develop, plan and produce the turn-key pilot plant / pilot container with our know-how and/or to your… -

Solar-/ Glas Industry

Treatment of process and flushing water plays an essential role in manufacturing and recycling chains. During processing, both highly… -

Technological Design / Feasibility

Our design combines physico-chemical and process-oriented engineering ideas with site-specific conditions. These are evaluated from… -

Flue Gas Desulfurization Plants

At the end of the processing chain of fossil energy generation, the flue gas requires desulfurization and denitrification to meet legal… -

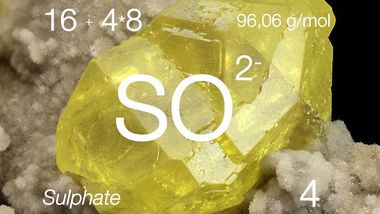

Sulphate Reduction

Sulphate is the anion of sulphuric acid dissociated in water. Furthermore sulphuric acid is the most used chemical substance applied in… -

Process pilot plants

Engineering and construction of turnkey process pilot plants for biotechnological or chemical/physical applications with expertise and many… -

Parameter Mercury

Mercury is an extremely toxic metal. It is coming more and more under critical observation and is being regulated to extremely low levels in… -

Parameter Vanadium

We are here to help you.

Please fill out the contact form and one of our product specialists will get in touch with you. If you have urgent questions, please contact us directly.