In many areas of the steel and automotive industry, contaminated rinsing water containing coolants/lubricants or other oils and greases is produced. We offer you tried-and-tested solutions for the concentration and treatment of your rinsing water flows.

The process engineering focal points here are the pre-separation of solids, phase separation and the downstream concentration stages. Experience has shown that thermal or membrane-based technologies (ultrafiltration) have proven successful for concentration.

Our range of services also includes the installation of peripheral plant components such as storage and transfer systems for handling and disposing of used oils or used coolants/lubricants or exhaust air treatment (either biofilters, adsorber material or wet scrubbers).

We modernise your existing plant technology for you or set up new systems with a connection to your production-related sources of waste. The focus here is on integrating new, more effective process steps, replacing/integrating measurement technology and/or replacing your outdated switchgear/control system.

When planning the modernisation or construction of a new plant for rinsing water treatment, particular attention is paid to the design and equipment of the plants in accordance with the applicable water and building laws and the Federal Immission Control Act (BImSchG).

-

Gas Scrubber

Gas scrubbing transfers heavy metals, salts, organic and anorganic components from the blast furnace and charged circulation gas or exhaust… -

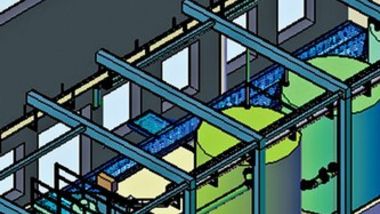

Industrial Plants

Construction and commissioning of process plants for water treatment is based on interdisciplinary experience. In addition to the mining and… -

Laboratory- / Pilot Tests

Laboratory testing and pilot testing are often compulsory for a sound concept development and optimal solution. We plan and execute these… -

Pilot Container

Based on your technology concept, we develop, plan and produce the turn-key pilot plant / pilot container with our know-how and/or to your… -

Technological Design / Feasibility

Our design combines physico-chemical and process-oriented engineering ideas with site-specific conditions. These are evaluated from… -

Cooling Water

The requirements for cooling water treatment vary considerably depending on the individual cooling system (open, semi-open, closed) and… -

Sulphate Reduction

Sulphate is the anion of sulphuric acid dissociated in water. Furthermore sulphuric acid is the most used chemical substance applied in… -

Process pilot plants

Engineering and construction of turnkey process pilot plants for biotechnological or chemical/physical applications with expertise and many… -

Parameter Mercury

Mercury is an extremely toxic metal. It is coming more and more under critical observation and is being regulated to extremely low levels in… -

Flushing Water

Many industrial fields in the steel and automotive industry yield flushing water contaminated by cooling and lubrication ingredients, or… -

Parameter Vanadium

-

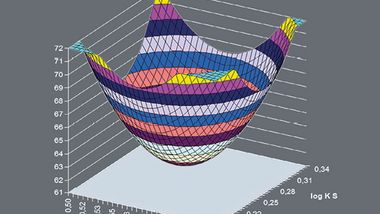

Metallurgical process simulation / modeling

Starting from first principles, (mass conservation, charge balance, mass action) models were developed for ion exchange (IX), ion exchange…

We are here to help you.

Please fill out the contact form and one of our product specialists will get in touch with you. If you have urgent questions, please contact us directly.