How much lithium is left in an old battery?

In times of raw material shortages and rising prices, the creation of sustainable processes in the value chain is becoming increasingly important. Many battery raw materials are classified by the EU as critical and strategically important. Closing the raw material cycle is therefore of great importance for the European battery industry.

Our advanced process engineering solutions for these material cycles play a decisive role in the efficient separation and processing of valuable raw materials, especially lithium. Through this process, we make a significant contribution to the efficient recycling of batteries in the field of electromobility. In this way, we not only increase resource efficiency, but also help to protect our environment.

Our expertise in battery recycling lies primarily in the downstream stages of the value chain. We specialize in handling pre-treated battery materials such as "black mass", cathode powders and slag.

We have extensive experience in characterizing these materials using advanced analytical methods and developing flowsheets for the selective leaching, separation and purification of lithium. Although our main focus is on lithium extraction, we are also able to develop and investigate combined extraction processes for other battery metals. Our expertise extends to processes such as solvent extraction (SX), ion exchange (IX) and membrane technologies for separation and purification, which ultimately yield lithium carbonate (Li2CO3) or lithium hydroxide (LiOH) as a product.

In addition, we pursue a holistic approach that includes the recycling of graphite and other components.

-

Mineral processing / hydrometallurgical test center

Specialized in the processing of minerals containing technology metals associated with NORM (Naturally Occurring Radioactive Material).… -

Industrial Plants

Construction and commissioning of process plants for water treatment is based on interdisciplinary experience. In addition to the mining and… -

Laboratory- / Pilot Tests

Laboratory testing and pilot testing are often compulsory for a sound concept development and optimal solution. We plan and execute these… -

Pilot Container

Based on your technology concept, we develop, plan and produce the turn-key pilot plant / pilot container with our know-how and/or to your… -

Technological Design / Feasibility

Our design combines physico-chemical and process-oriented engineering ideas with site-specific conditions. These are evaluated from… -

Process pilot plants

Engineering and construction of turnkey process pilot plants for biotechnological or chemical/physical applications with expertise and many… -

Metal separation / refining – from test work to engineering

We are experienced in solving hydrometallurgical, geochemical and process engineering challenges. Our experts have designed and… -

Metallurgical process simulation / modeling

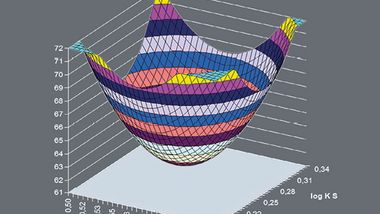

Starting from first principles, (mass conservation, charge balance, mass action) models were developed for ion exchange (IX), ion exchange…

We are here to help you.

Please fill out the contact form and one of our product specialists will get in touch with you. If you have urgent questions, please contact us directly.