Chemical-physical (CP) plants for the treatment of waste solutions containing oil and heavy metals, acidic, alkaline and neutral waste solutions have been an integral part of many disposal sites for years.

The requirements for the effluent quality of these systems have constantly increased in recent years, with the result that various systems no longer fulfil the applicable standards. In addition to fulfilling legal requirements, the focus today is on environmentally friendly and resource-saving operation. At the same time, a high level of efficiency and reliability is required.

We plan and build a complete plant with reception and storage areas, process stages for treating organic and inorganic liquid waste, including sludge treatment and the necessary ancillary systems such as exhaust air treatment and compressed air supply, customised for you. Our technological expertise ranges from simple precipitation/flocculation to emulsion splitting and membrane processes.

Authorisation plays a key role in the planning and construction of a CP system. We are happy to assist you in discussions with the responsible authorities and the technical parties involved. It is standard practice for us to prepare the necessary authorisation documents in accordance with BImSchG, UVP and water legislation (WHG, VAwS).

We are available for the planning, including authorisation support and the construction of your robust and economical CP system.

-

Chemical-physical Plants

Chemical-physical (CP) plants for processing oil and heavy metals, acid, alkaline and neutral waste solutions have long been considered… -

Industrial Plants

Construction and commissioning of process plants for water treatment is based on interdisciplinary experience. In addition to the mining and… -

Laboratory- / Pilot Tests

Laboratory testing and pilot testing are often compulsory for a sound concept development and optimal solution. We plan and execute these… -

Pilot Container

Based on your technology concept, we develop, plan and produce the turn-key pilot plant / pilot container with our know-how and/or to your… -

Technological Design / Feasibility

Our design combines physico-chemical and process-oriented engineering ideas with site-specific conditions. These are evaluated from… -

Incineration Plants

The multi-level removal of pollutants from flue gas in waste incineration plants is based on dry, semi-dry and wet processes. The reduction… -

Sulphate Reduction

Sulphate is the anion of sulphuric acid dissociated in water. Furthermore sulphuric acid is the most used chemical substance applied in… -

Process pilot plants

Engineering and construction of turnkey process pilot plants for biotechnological or chemical/physical applications with expertise and many… -

Bioenergy Test Plants (Biogas)

7,100 biogas plants with a capacity of approx. 2,800 MW (2011) produce energy, heat and fuel in Germany. Our biogas test plants help to… -

Parameter Mercury

Mercury is an extremely toxic metal. It is coming more and more under critical observation and is being regulated to extremely low levels in… -

Metal separation / refining – from test work to engineering

We are experienced in solving hydrometallurgical, geochemical and process engineering challenges. Our experts have designed and… -

Parameter Vanadium

-

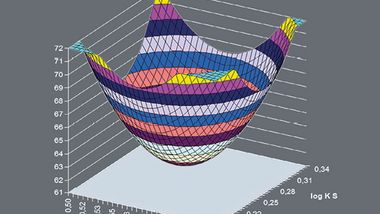

Metallurgical process simulation / modeling

Starting from first principles, (mass conservation, charge balance, mass action) models were developed for ion exchange (IX), ion exchange…

We are here to help you.

Please fill out the contact form and one of our product specialists will get in touch with you. If you have urgent questions, please contact us directly.